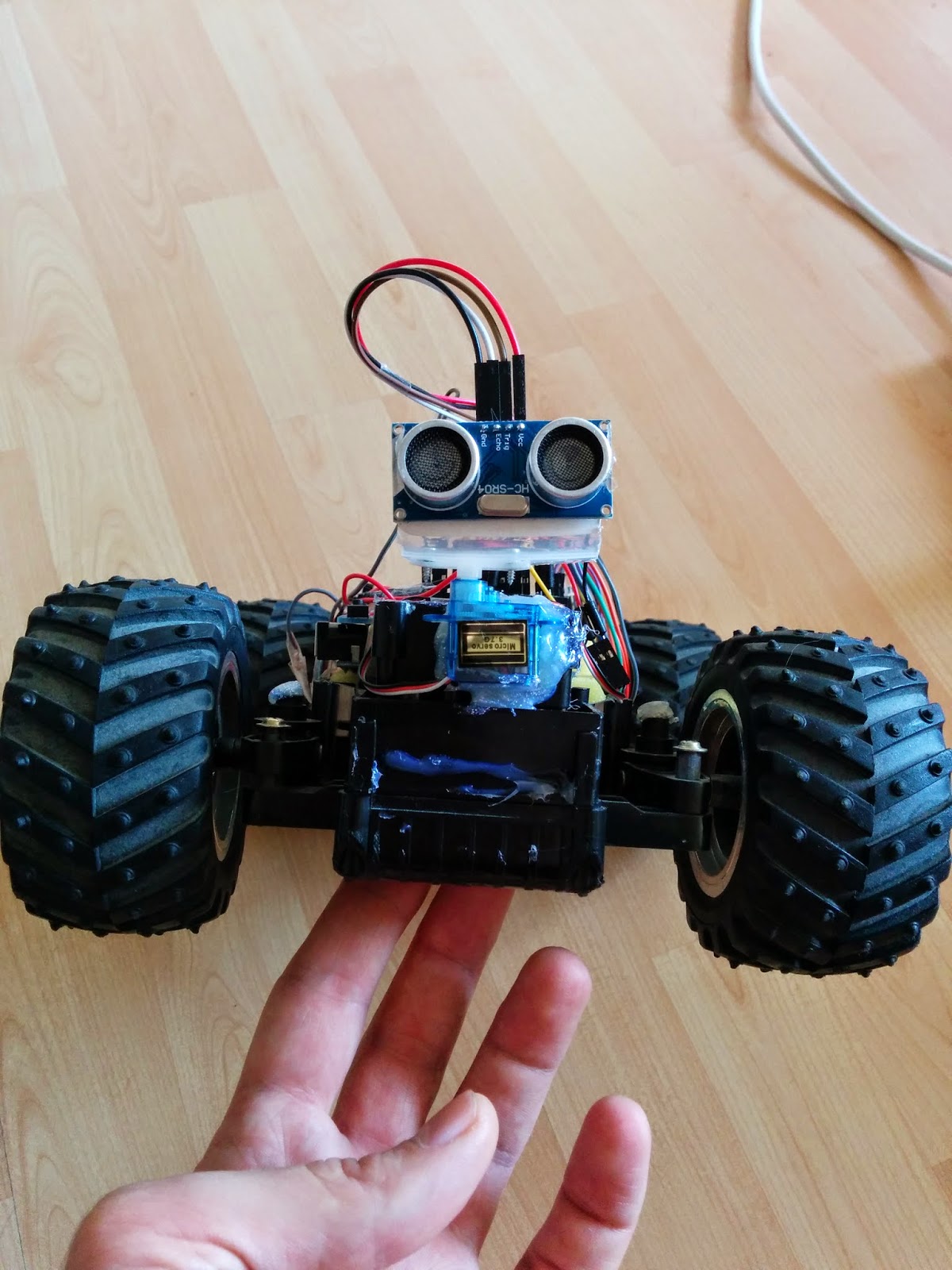

This is my very first Arduino project. I made a robot by using a RC Car that I found in a recycling depot. This project is structured in 3 main parts: Material List, Physical Connection and Coding.

Before we start I presume you have some basic knowledge about Arduino and C++ programming. If not I invite you to first spend some time on the official Arduino website: www.arduino.cc

Material list:

- Arduino Uno R3- L298N Motor Drive Board

- HC-SR04 Echolocation Sensor

- Tower Pro Micro servo 9g - servo motor

- red LED

- 2 x DC motors

- 9V battery

- wire jumpers: Male/Male, Male/Female, Female/Female.

- RC Car chassis and wheels

In my case DC motors were on the RC Car that I recycled so wasn't necessary to buy them. So if you find any broken RC Car toy I suggest to use that instead of buying a new one.

First step was to repair mechanical problems of the RC Car and remove unnecessary parts and I just discovered the power of the glue gun :-)

Physical connection:

When the chassis was ready the next important step was to connect the motors, sensors and all boards to Arduino. Please follow the instructions and read the schematics. Double-check each connection and be sure that pins are connected properly.HC-SR04 Echolocation Sensor to Arduino Uno R3:

(HC-SR04: used to scan the surrounding and help the robot to find his way)

- Trig pin to I/O pin 13

- Echo pin to I/O pin 12

- VCC pin to 5V (power)

- GND pin to GND (ground)

Tower Pro Micro servo 9g to Arduino Uno R3:

(used to rotate HC-SR04 sensor)

+ (red wire) to 5V pin

- (black wire) to GND pin

signal (yellow wire) to I/O pin 9

L298N Motor Drive Board to Arduino Uno R3:

(L298N Board: used to control the DC motors of the robot)

- ENA pin to I/O pin 5

- ENB pin to I/O pin 3

- IN1 pin to I/O pin 2

- IN2 pin to I/O pin 4

- IN3 pin to I/O pin 6

- IN4 pin to I/O pin 7

- 5V pin to 5V pin

- GND pin to GND pin

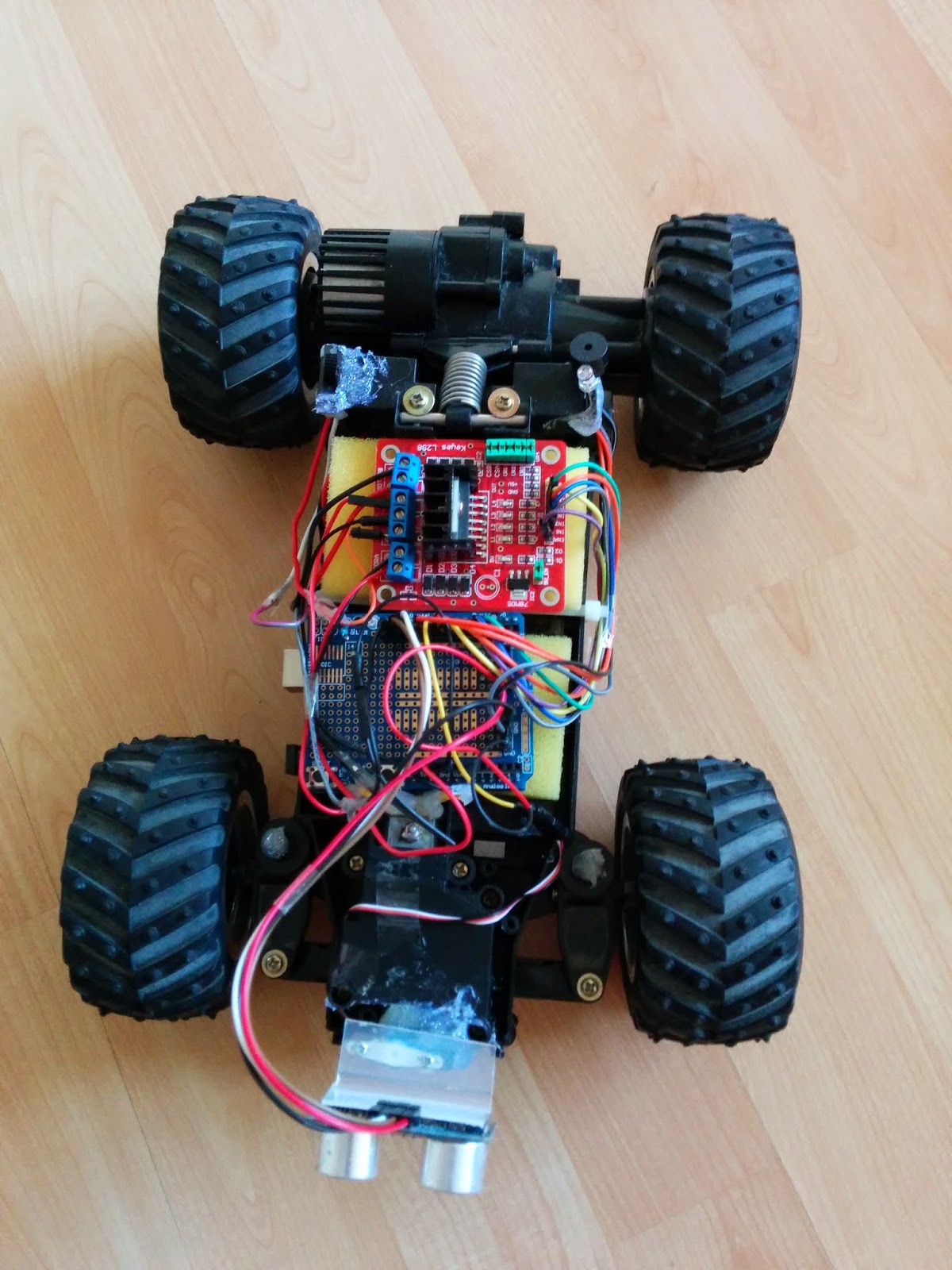

Front DC Motor to L298N Motor Drive Board:

(to control direction of the robot: left/right)

+ to Motor A Output 1

- to Motor A Output 2

Rear DC Motor to L298N Motor Drive Board

(to control propulsion of the robot: forward/backward)

+ to Motor B Output 1

- to Motor B Output 2

Battery connection:

- to GND pin on Arduino

+ to VMS on L298N Board

for control of the power you can attach a button between the + wire of the battery and VMS pin on L298N Board

LED to Arduino:

(turns ON when the robot is moving backward)

+ to I/O pin 10

- to GND

Important Tips:

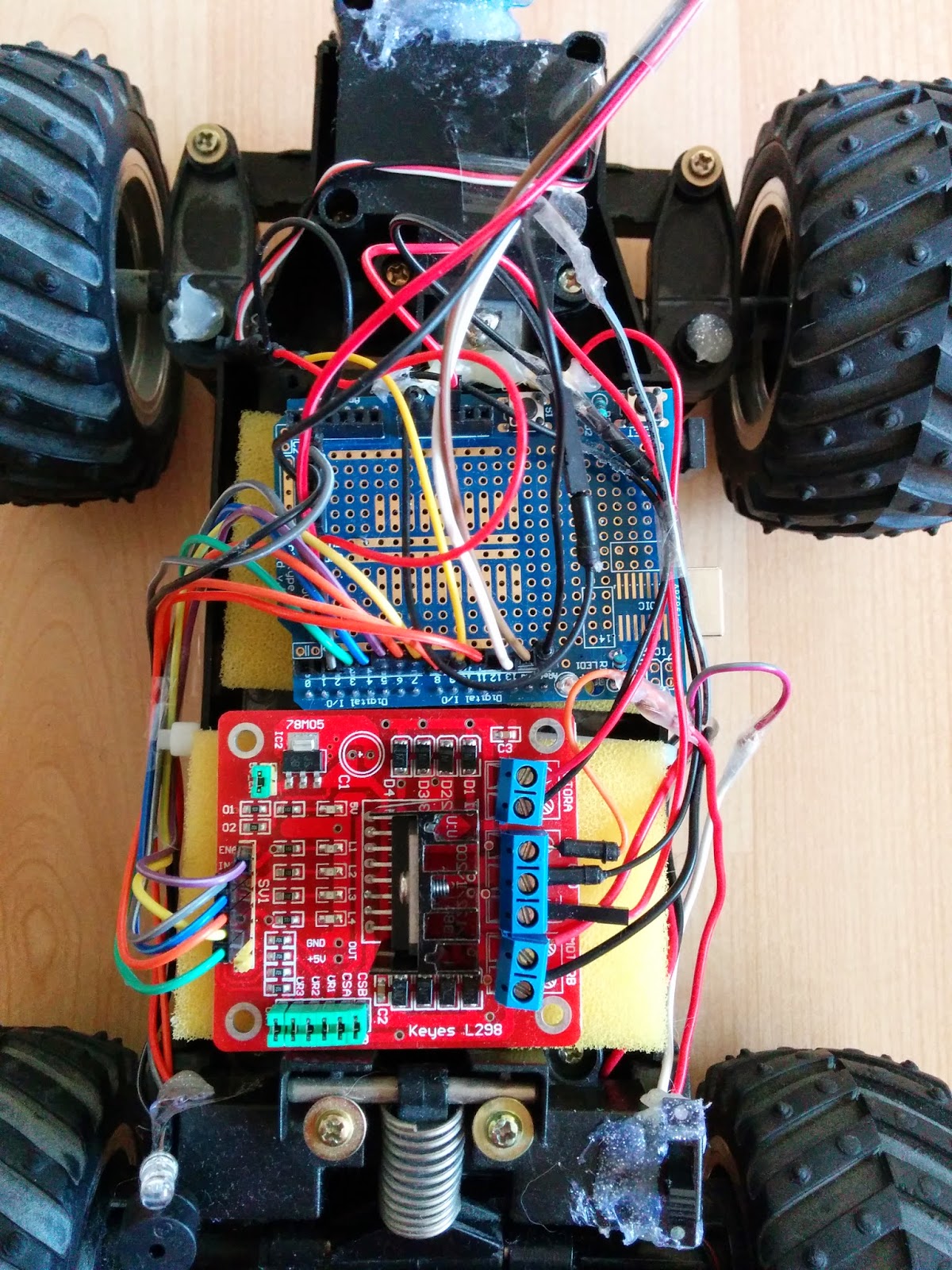

- Connect one component at the time and test it. As you can see in the photos below I've done the same.

- Since there are too many components that needs to connect to the battery I used a prototyping shield, this one multiplies the 5V pins and GND pins. On the other hand on a prototyping shield you are able to multiply any other pin from Arduino Uno R3. Don't know how a prototyping shield looks like? Check the image above.

Coding:

Important Tips:The code below may need to be adapted to your robot. Depends on the size of the robot there can occur some changes.

#include <Servo.h>

#define trig 13

#define echo 12

Servo myservo;

int servoLeft = 10; //angle of microservo rotation to scan on left

int servoForward = 45;

int servoRight = 100; //angle of microservo rotation to scan on right

int a=0;

int ena = 5;

int enb = 3;

int in1 = 2;

int in2 = 4;

int in3 = 6;

int in4 = 7;

int czas, dist1, dist2, dist3;

void setup() {

// servo pin definition

myservo.attach(9);

//buzzer

pinMode(11, OUTPUT);

//light

pinMode(10, OUTPUT);

//ultrasonic sensor

pinMode(trig, OUTPUT);

pinMode(echo, INPUT);

//motors

pinMode(ena, OUTPUT);

pinMode(enb, OUTPUT);

pinMode(in1, OUTPUT);

pinMode(in2, OUTPUT);

pinMode(in3, OUTPUT);

pinMode(in4, OUTPUT);

}

void loop() {

scanLeft();

delay(250);

scanRight();

delay(250);

scanForward();

delay(250);

if( dist3<30){

moveBackward();

digitalWrite(10, HIGH);

delay(1000);

digitalWrite(10, LOW);

moveStop();

}

if(dist2>50 && dist1<20){

turnRight();

delay(500);

moveForward();

delay(1000);

moveStop();

a=2;

}

if(dist1>50 && dist2<20){

turnLeft();

delay(500);

moveForward();

delay(1000);

moveStop();

a=3;

}

if(dist3>dist2 && dist3>dist1 && dist3>50){

if(a==2) {

lamijlocdindreapta();

}

if(a==3) {

lamijlocdinstanga();

}

moveForward();

delay(1000);

moveStop();

a=1;

}

if(dist2>dist3 && dist2>dist1 && dist2>50){

turnRight();

delay(500);

moveForward();

delay(1000);

moveStop();

a=2;

}

if(dist1>dist2 && dist1>dist3 && dist1>50){

turnLeft();

delay(500);

moveForward();

delay(1000);

moveStop();

a=3;

}

}

void scanForward(){

myservo.write(servoForward);

digitalWrite(trig, HIGH);

delay(500);

digitalWrite(trig, LOW);

czas = pulseIn(echo, HIGH);

dist3 = (czas/2)/29.1;

}

void scanRight(){

myservo.write(servoRight);

delay(50);

digitalWrite(trig, HIGH);

delay(500);

digitalWrite(trig, LOW);

czas = pulseIn(echo, HIGH);

dist2 = (czas/2)/29.1;

}

void scanLeft(){

myservo.write(servoLeft);

delay(50);

digitalWrite(trig, HIGH);

delay(500);

digitalWrite(trig, LOW);

czas = pulseIn(echo, HIGH);

dist1 = (czas/2)/29.1;

}

void moveForward(){

motorB(2, 60);

motorA(0, 0);

}

void lamijlocdindreapta(){

turnLeft();

delay(200);

}

void lamijlocdinstanga(){

turnRight();

delay(200);

}

void moveBackward(){

motorB(1, 80);

motorA(0, 0);

}

void turnLeft(){

motorA(2, 50);

motorB(0, 0);

}

void turnRight(){

motorA(1, 50);

motorB(0, 0);

}

void moveStop(){

motorA(0, 0);

motorB(0, 0);

}

void buzzerOn(){

tone(8, 440, 200);

}

void lightOn(){

digitalWrite(10, HIGH);

delay(500);

digitalWrite(10, LOW);

}

//****************** Motor A control *******************

void motorA(int mode, int percent)

{

//change the percentage range of 0 -> 100 into the PWM

//range of 0 -> 255 using the map function

int duty = map(percent, 0, 100, 0, 255);

switch(mode)

{

case 0: //disable/coast

digitalWrite(ena, LOW); //set enable low to disable A

break;

case 1: //turn clockwise

//setting IN1 high connects motor lead 1 to +voltage

digitalWrite(in1, HIGH);

//setting IN2 low connects motor lead 2 to ground

digitalWrite(in2, LOW);

//use pwm to control motor speed through enable pin

analogWrite(ena, duty);

break;

case 2: //turn counter-clockwise

//setting IN1 low connects motor lead 1 to ground

digitalWrite(in1, LOW);

//setting IN2 high connects motor lead 2 to +voltage

digitalWrite(in2, HIGH);

//use pwm to control motor speed through enable pin

analogWrite(ena, duty);

break;

case 3: //brake motor

//setting IN1 low connects motor lead 1 to ground

digitalWrite(in1, LOW);

//setting IN2 high connects motor lead 2 to ground

digitalWrite(in2, LOW);

//use pwm to control motor braking power

//through enable pin

analogWrite(ena, duty);

break;

}

}

//****************** Motor B control *******************

void motorB(int mode, int percent)

{

//change the percentage range of 0 -> 100 into the PWM

//range of 0 -> 255 using the map function

int duty = map(percent, 0, 100, 0, 255);

switch(mode)

{

case 0: //disable/coast

digitalWrite(enb, LOW); //set enable low to disable B

break;

case 1: //turn clockwise

//setting IN3 high connects motor lead 1 to +voltage

digitalWrite(in3, HIGH);

//setting IN4 low connects motor lead 2 to ground

digitalWrite(in4, LOW);

//use pwm to control motor speed through enable pin

analogWrite(enb, duty);

break;

case 2: //turn counter-clockwise

//setting IN3 low connects motor lead 1 to ground

digitalWrite(in3, LOW);

//setting IN4 high connects motor lead 2 to +voltage

digitalWrite(in4, HIGH);

//use pwm to control motor speed through enable pin

analogWrite(enb, duty);

break;

case 3: //brake motor

//setting IN3 low connects motor lead 1 to ground

digitalWrite(in3, LOW);

//setting IN4 high connects motor lead 2 to ground

digitalWrite(in4, LOW);

//use pwm to control motor braking power

//through enable pin

analogWrite(enb, duty);

break;

}

}

i make the pingbot...but one motor is not working...plzz help me

ReplyDeleteThanks, I want to build a 6 motor Rover, Sensor, Arduino and so on for my 10 year old grandson. You have done 90% of the work for me with this source code.

ReplyDeletelarystoy

This unique contest car has a designer's designated operating associated with 3-years and more mature, so I wasn't ready for how a 5 year old would operate it. Those who have played with my RADIO MANAGED models before, are teenagers, and they drive the vehicles non-aggressively. best rc cars under 100

ReplyDeleteAdmiring the time and effort you put into your blog and detailed information you offer!.. Wedding Toronto Limousine

ReplyDelete